A cada etapa cumprida, um inspetor de qualidade atesta o serviço executado, registrando sua conformidade. Após o término da blindagem, são efetuados rigorosos testes de controle de qualidade como: infiltração de água, barulho e aproximadamente mais de 420 itens são checados para conferir e garantir que todos os acabamentos e detalhes estéticos estejam perfeitos.

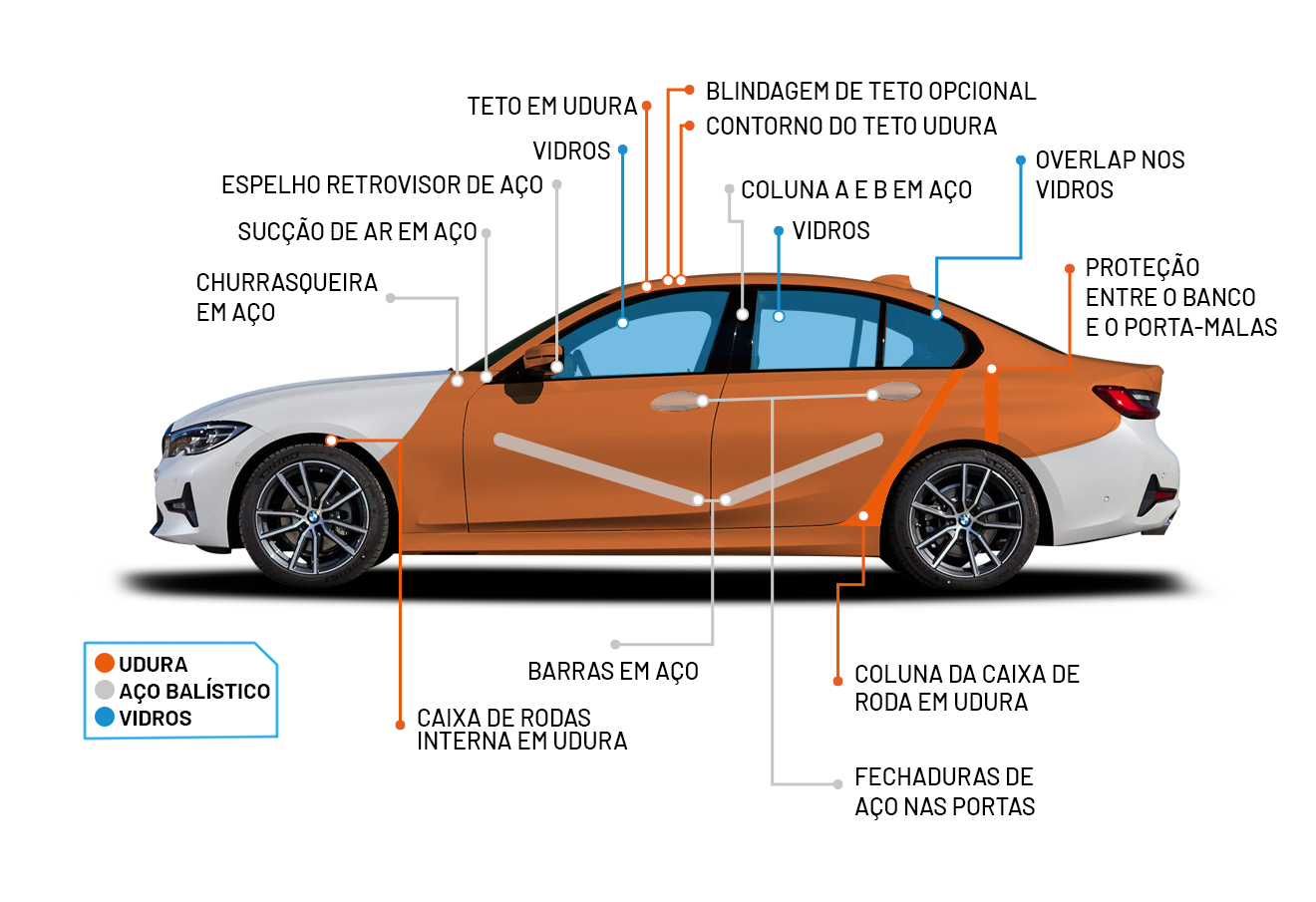

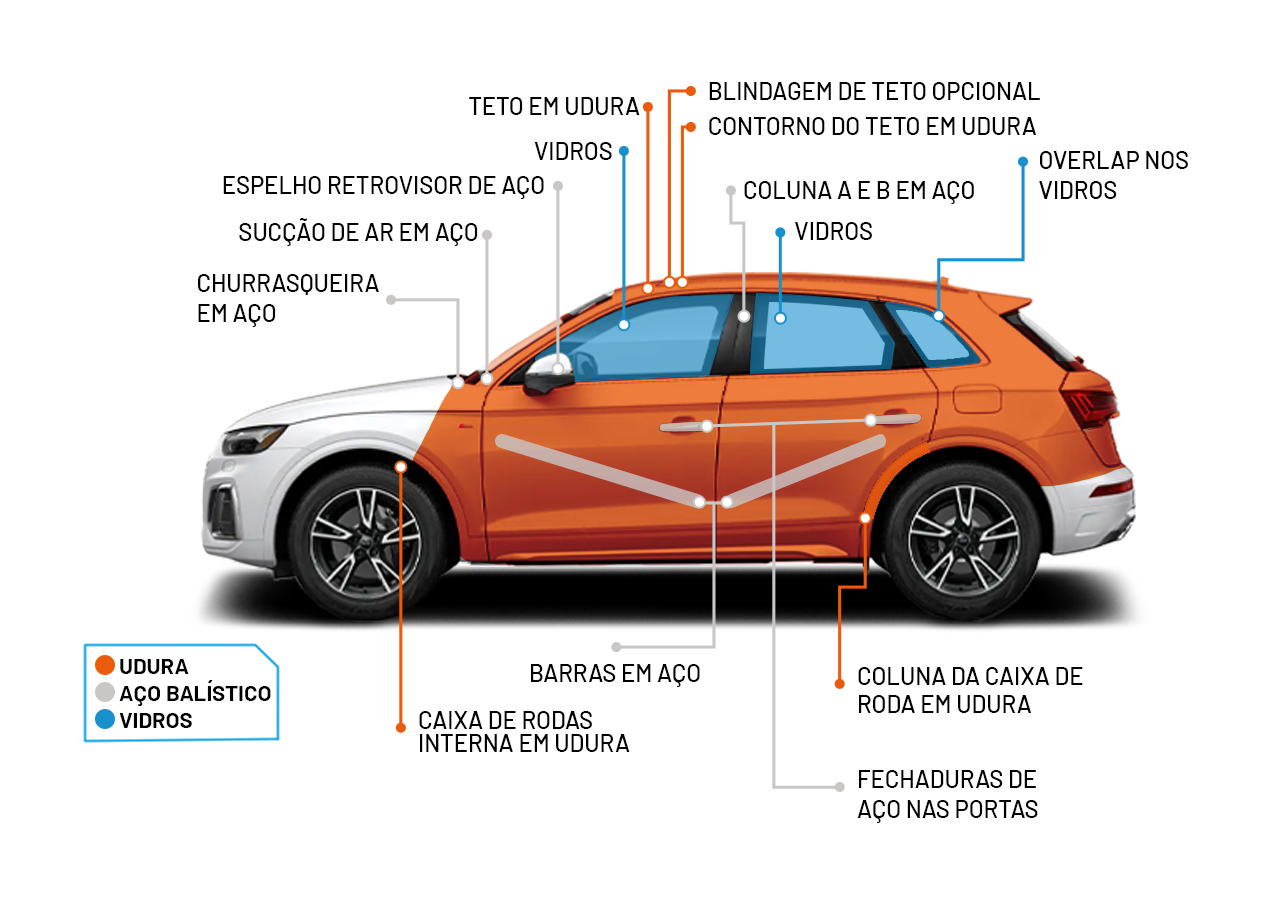

A Avallon utiliza vidros blindados com Steel (moldura de aço nas bordas), com tecnologia de última geração, proporcionando aparência original. Muito leve e de alta resistência, possuem uma película interna que protege os ocupantes de possíveis estilhaços. Quase impossível identificá-los, para que possa transitar sem ser identificado como blindado, garantindo assim o conforto e a dirigibilidade segura do veículo.

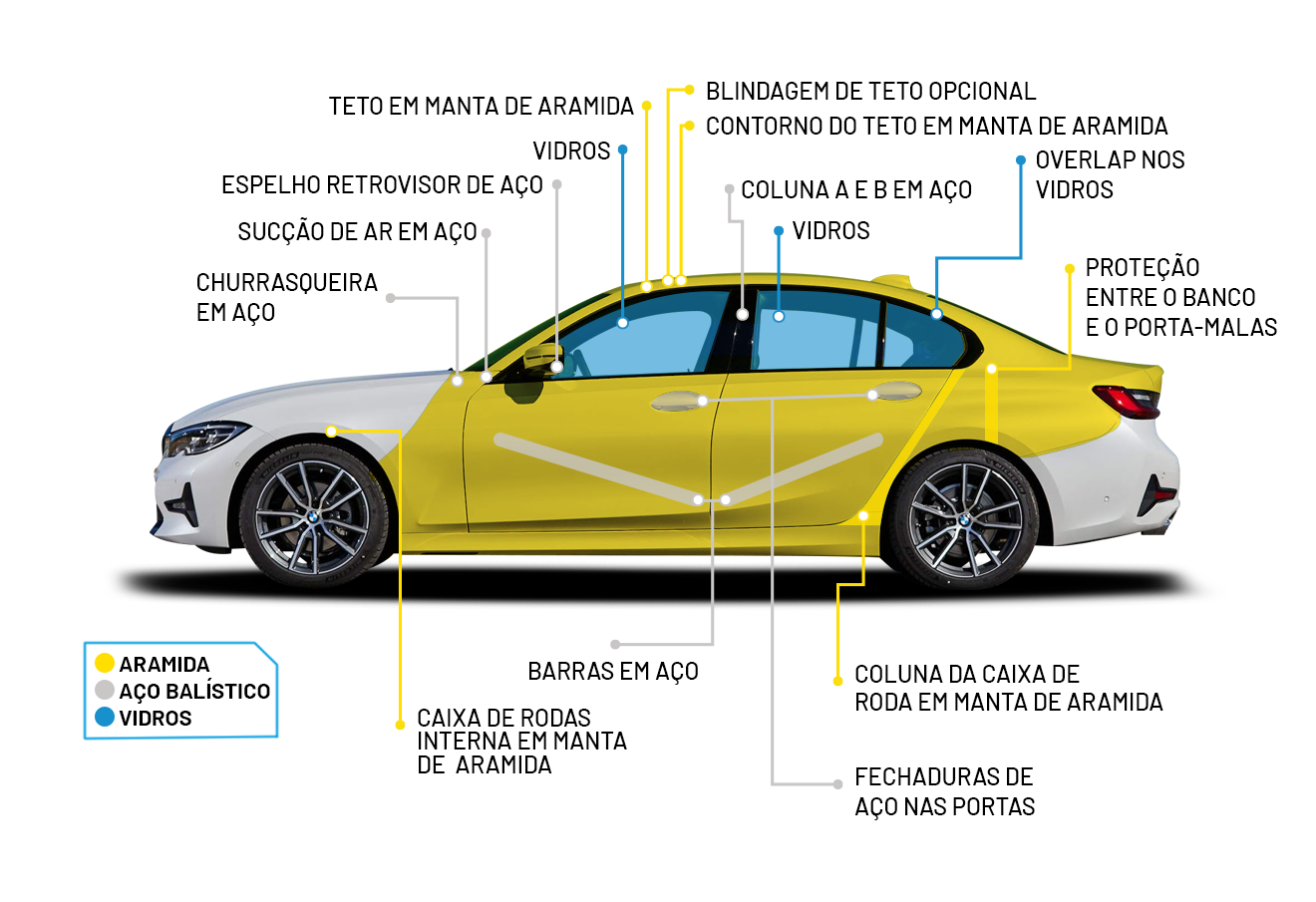

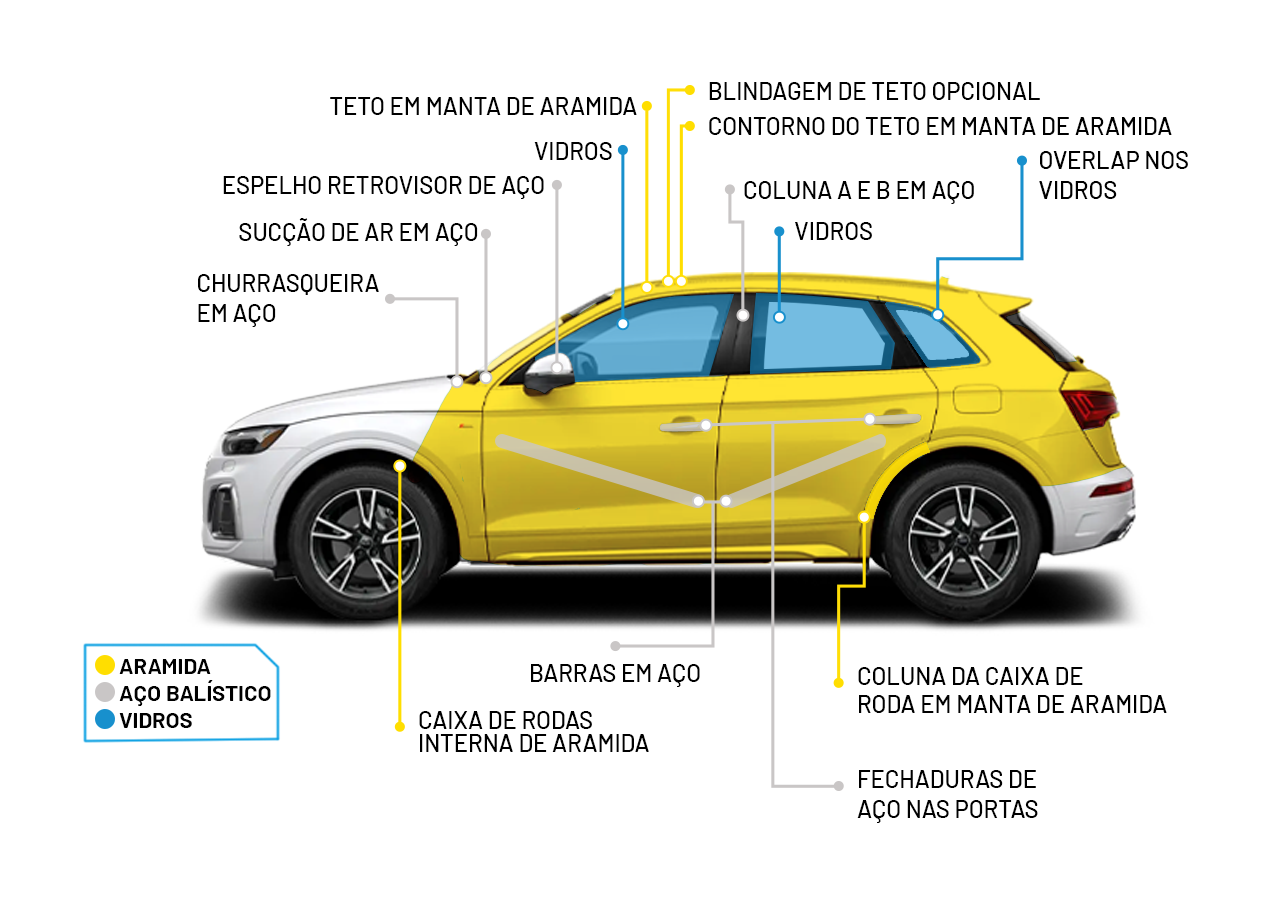

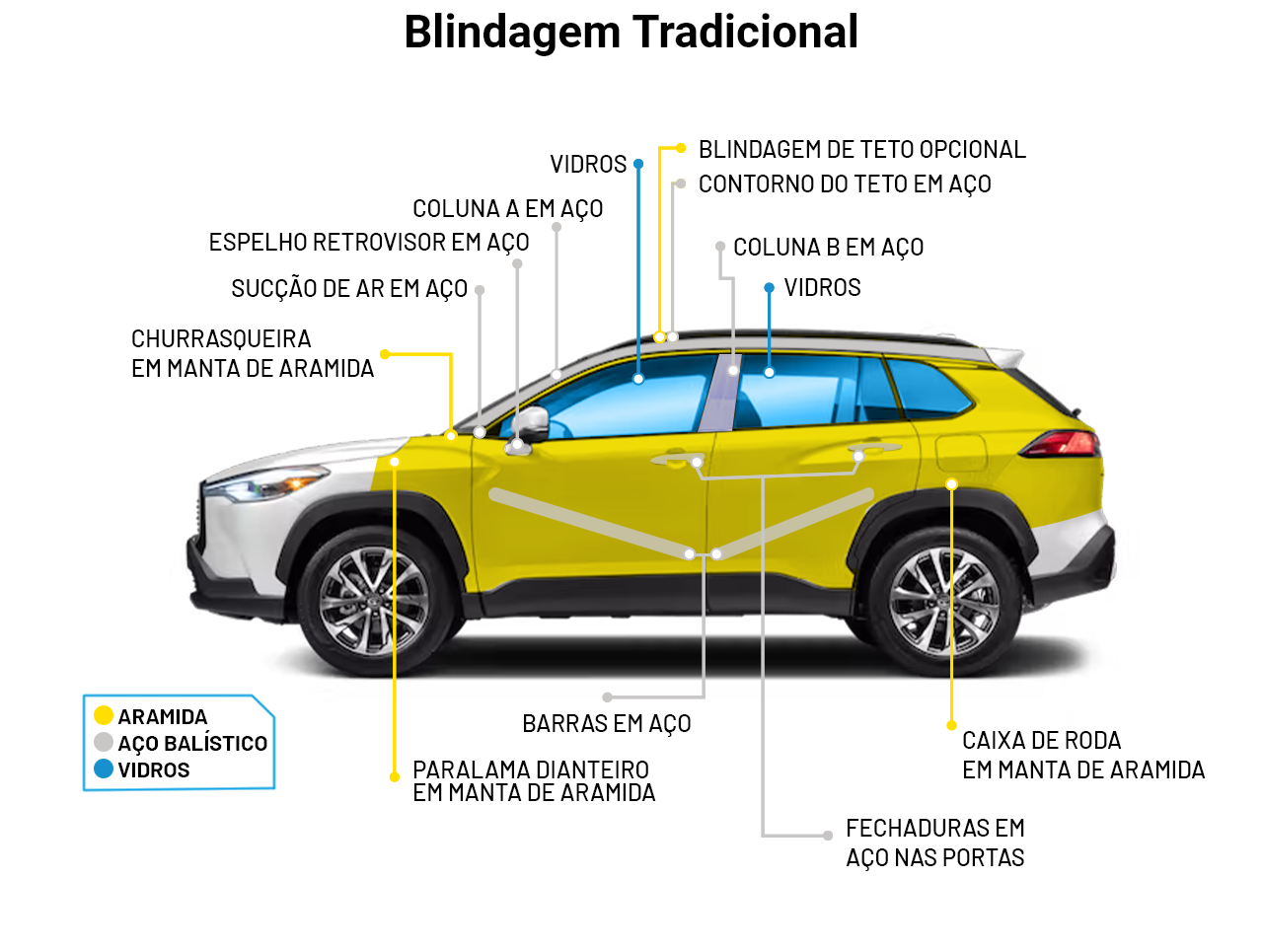

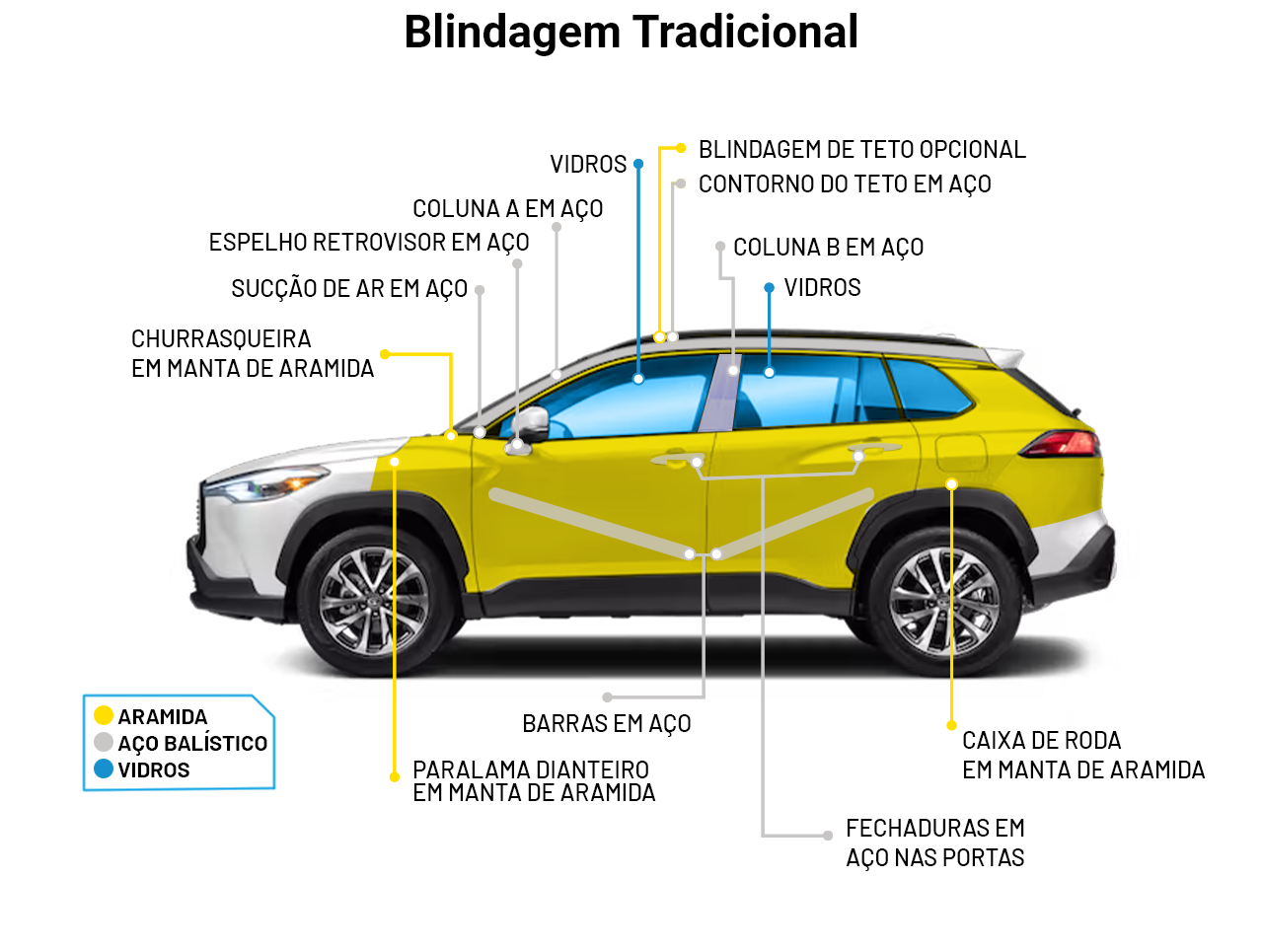

A tecnologia utilizada pela Avallon, reveste o habitáculo do veículo em mantas de aramida e painéis emborrachados com neoprene em ambos os lados. Por seu poder de elasticidade, peso, aderência e flexibilidade, facilita a adaptação nas estruturas, sem interferir no espaço interior e aparência original do veículo. Aplicados em módulos inteiros recortados de acordo com a área a ser fixada, evitando emendas, que se tornariam pontos vulneráveis.

Aço balístico inoxidável é utilizado em toda estrutura do veículo, como: colunas A e B, barras das portas, fechaduras e em outros locais onde não há fixação total da manta de aramida, eliminando pontos vulneráveis e reforçando toda estrutura original do veículo. Todas as peças são moldadas individualmente, cobertas por resina automotiva e revestidas internamente com E.V.A (antiatrito que inibe o contato do aço com a lataria do automóvel). Com este processo de blindagem, o veículo não terá ruídos internos fora do padrão original de fabricação.

A resposta é: sim! Os vidros dianteiros permanecem operáveis, podendo abaixar até 90% dependendo do modelo. Já os traseiros, por questão de segurança, são mantidos fixos – e em alguns casos, por solicitação do cliente, eles podem ser abaixados, mas com restrições.

Lembre-se que se deve evitar ao máximo abaixar os vidros para que não comprometa a segurança dos passageiros e haja vulnerabilidade à possíveis situações de risco.

Não, pois além de não garantir a segurança do usuário, ela não é autorizada pelo Exército.

PESSOA FÍSICA

PESSOA JUDÍDICA

Trata-se de um dispositivo que mantém o pneu preso à roda e, mesmo furado, permite o deslocamento por alguns quilômetros.

É o processo de descolamento entre as lâminas de vidro e de policarbonato, que constituem o pacote balístico de um vidro blindado.

Nossa blindagem foi desenvolvida por engenheiros e técnicos altamente qualificados,

utilizando conceitos que foram consolidados e aprovados como seguros. São mais de 120 carros blindados por mês.

A cada etapa cumprida, um inspetor de qualidade atesta o serviço executado, registrando sua conformidade. Após o término da blindagem, são efetuados rigorosos testes de controle de qualidade como: infiltração de água, barulho e aproximadamente mais de 420 itens são checados para conferir e garantir que todos os acabamentos e detalhes estéticos estejam perfeitos.

A Avallon utiliza vidros blindados com Steel (moldura de aço nas bordas), com tecnologia de última geração, proporcionando aparência original. Muito leve e de alta resistência, possuem uma película interna que protege os ocupantes de possíveis estilhaços. Quase impossível identificá-los, para que possa transitar sem ser identificado como blindado, garantindo assim o conforto e a dirigibilidade segura do veículo.

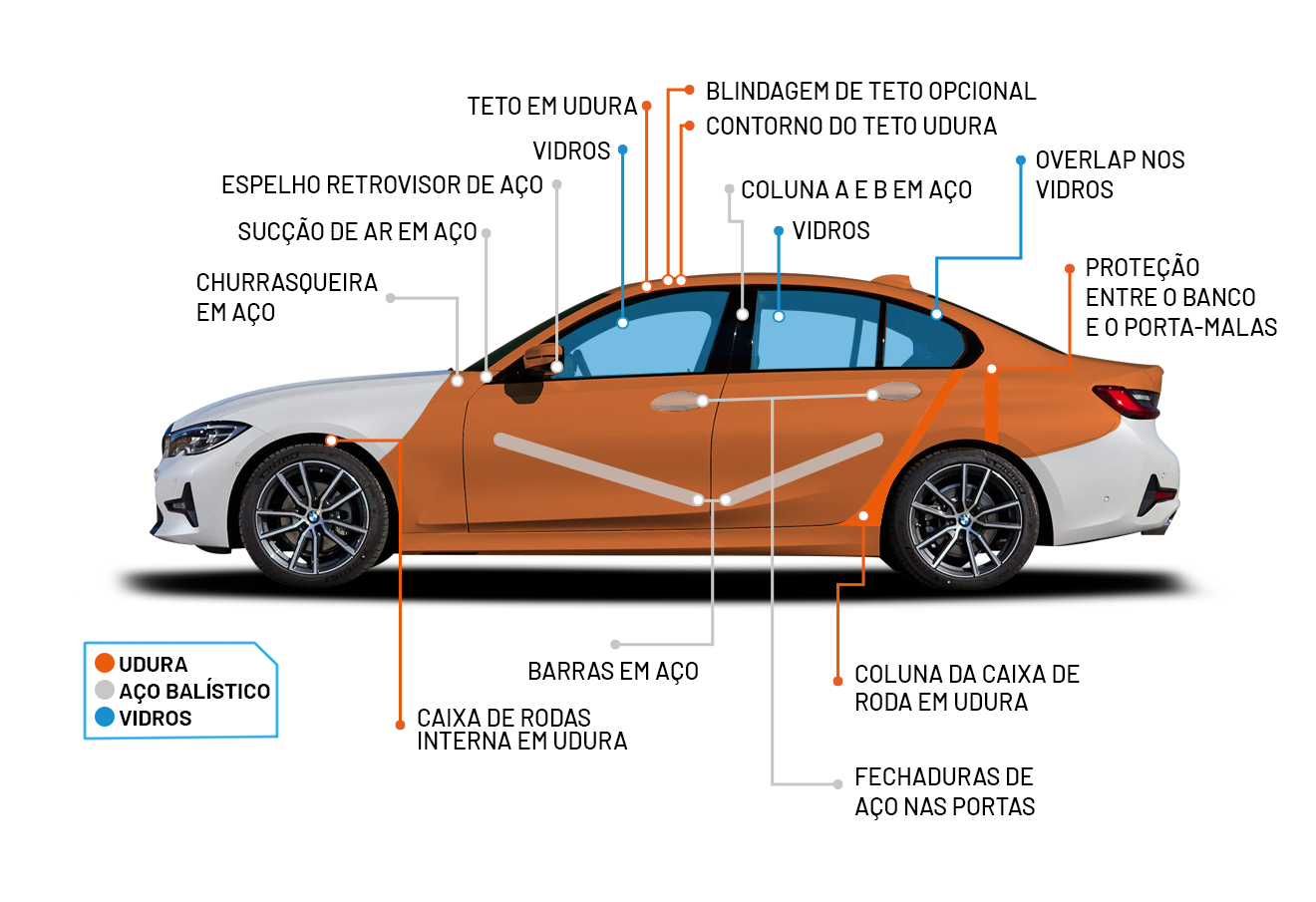

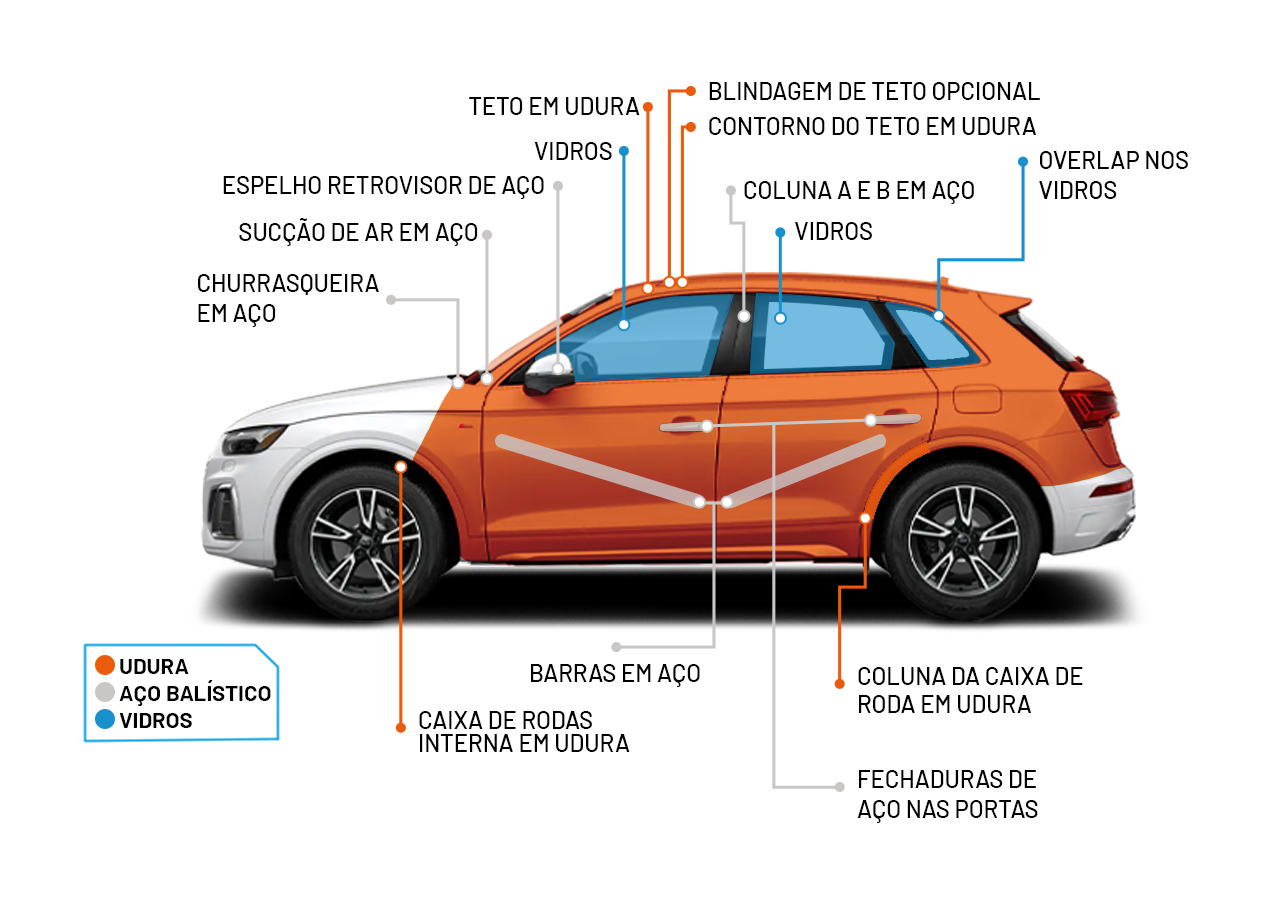

A tecnologia utilizada pela Avallon reveste o habitáculo do veículo em mantas de aramida. Por seu poder de elasticidade, peso, aderência e flexibilidade, facilita a adaptação nas estruturas, sem interferir no espaço interior e aparência original do veículo. Aplicados em módulos inteiros recortados de acordo com a área a ser fixada, evitando emendas, que se tornariam pontos vulneráveis.

Aço balístico inoxidável é utilizado na estrutura do veículo, onde não há fixação total da manta de aramida, eliminando pontos vulneráveis e reforçando toda estrutura original do veículo. Todas as peças são moldadas individualmente, cobertas por resina automotiva e revestidas internamente com E.V.A (antiatrito que inibe o contato do aço com a lataria do automóvel). Com este processo de blindagem, o veículo não terá ruídos internos fora do padrão original de fabricação.

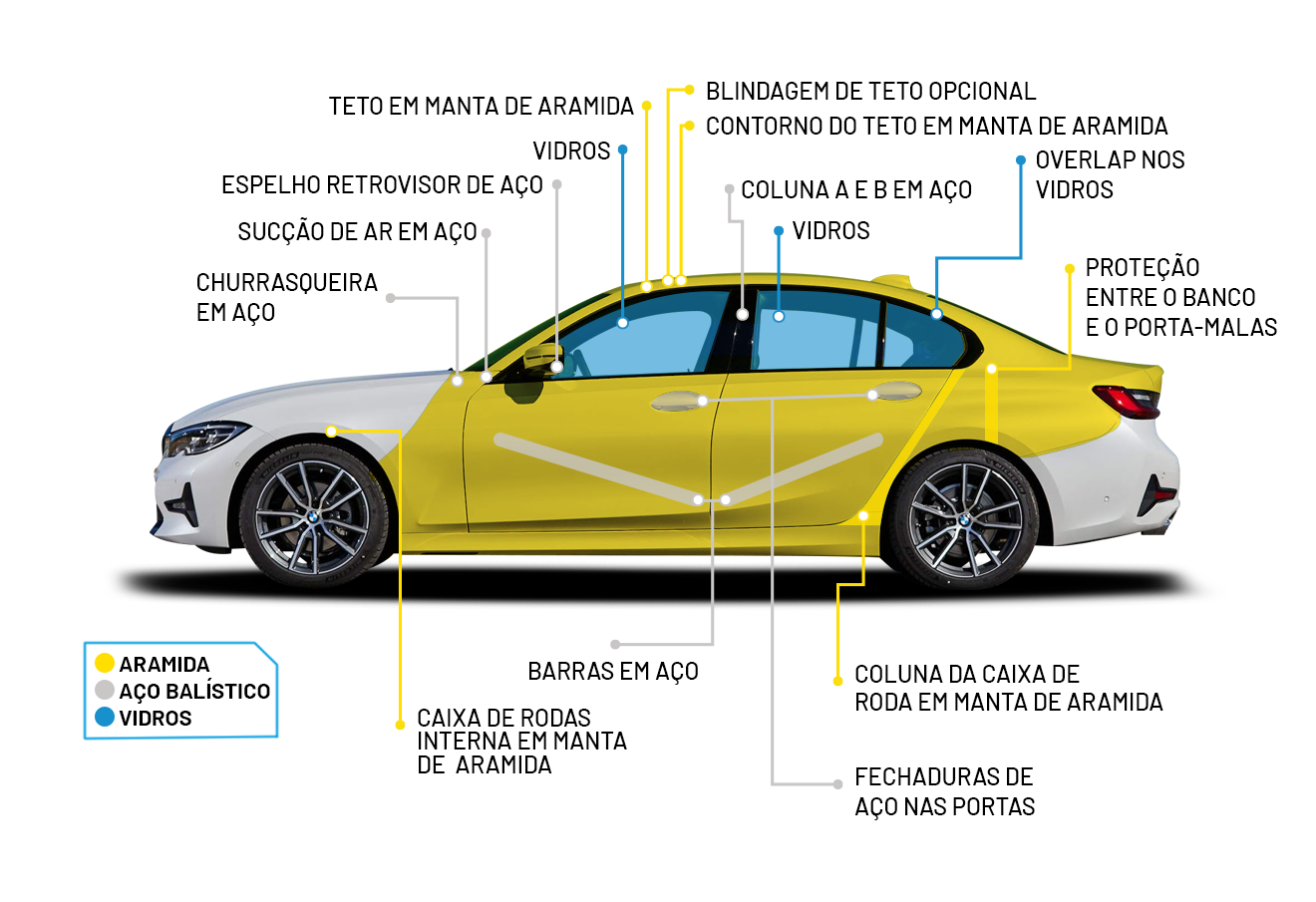

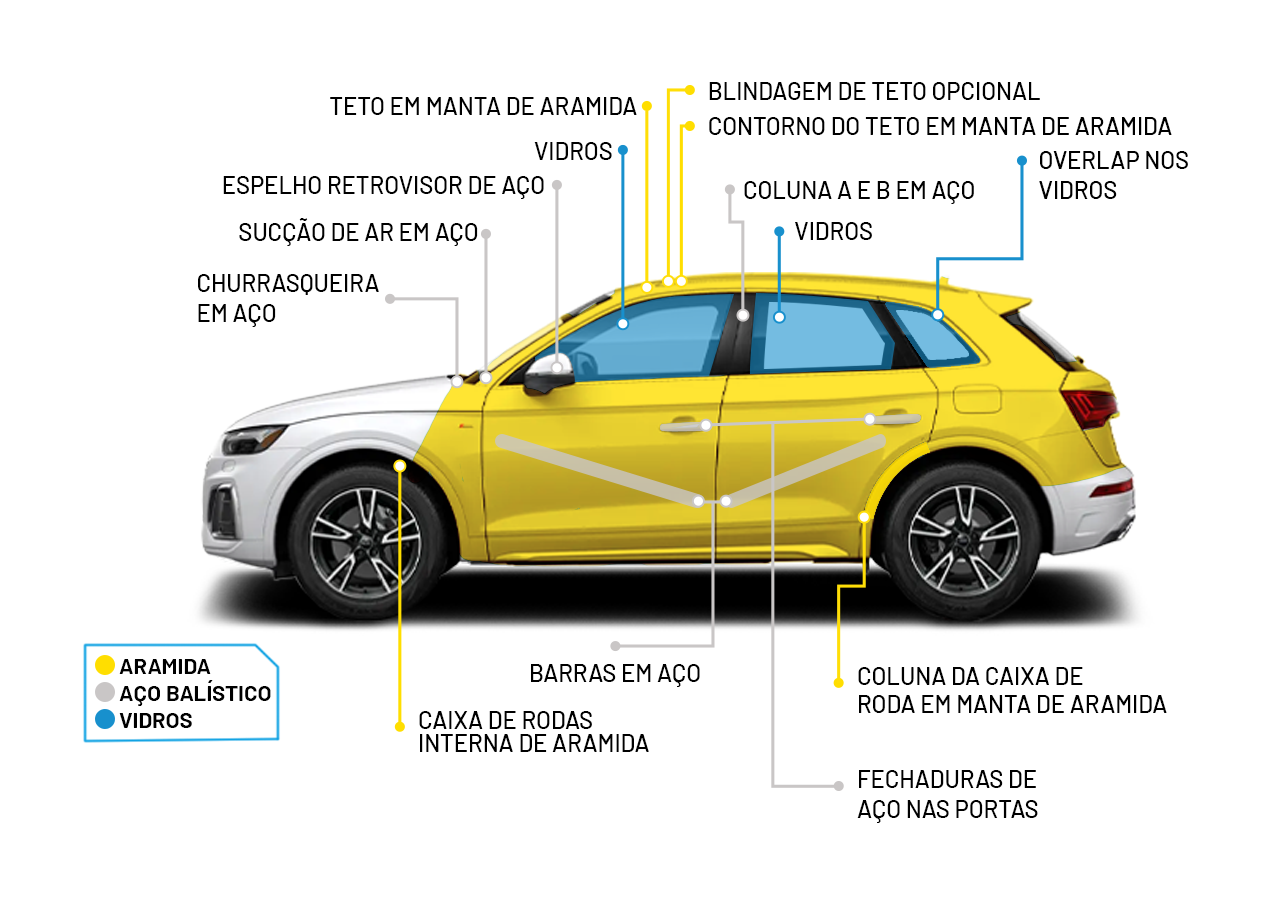

A Avallon utiliza vidros blindados com Steel (moldura de aço nas bordas), com tecnologia de última geração, proporcionando aparência original. Muito leve e de alta resistência, possuem uma película interna que protege os ocupantes de possíveis estilhaços. Quase impossível identificá-los, para que possa transitar sem ser identificado como blindado, garantindo assim o conforto e a dirigibilidade segura do veículo.

A tecnologia utilizada pela Avallon, reveste o habitáculo do veículo em mantas de aramida e painéis emborrachados com neoprene em ambos os lados. Por seu poder de elasticidade, peso, aderência e flexibilidade, facilita a adaptação nas estruturas, sem interferir no espaço interior e aparência original do veículo. Aplicados em módulos inteiros recortados de acordo com a área a ser fixada, evitando emendas, que se tornariam pontos vulneráveis.

Aço balístico inoxidável é utilizado em toda estrutura do veículo, como: colunas A e B, barras das portas, fechaduras e em outros locais onde não há fixação total da manta de aramida, eliminando pontos vulneráveis e reforçando toda estrutura original do veículo. Todas as peças são moldadas individualmente, cobertas por resina automotiva e revestidas internamente com E.V.A (antiatrito que inibe o contato do aço com a lataria do automóvel). Com este processo de blindagem, o veículo não terá ruídos internos fora do padrão original de fabricação.

A resposta é: sim! Os vidros dianteiros permanecem operáveis, podendo abaixar até 90% dependendo do modelo. Já os traseiros, por questão de segurança, são mantidos fixos – e em alguns casos, por solicitação do cliente, eles podem ser abaixados, mas com restrições.

Lembre-se que se deve evitar ao máximo abaixar os vidros para que não comprometa a segurança dos passageiros e haja vulnerabilidade à possíveis situações de risco.

Não, pois além de não garantir a segurança do usuário, ela não é autorizada pelo Exército.

PESSOA FÍSICA

PESSOA JUDÍDICA

Trata-se de um dispositivo que mantém o pneu preso à roda e, mesmo furado, permite o deslocamento por alguns quilômetros.

É o processo de descolamento entre as lâminas de vidro e de policarbonato, que constituem o pacote balístico de um vidro blindado.